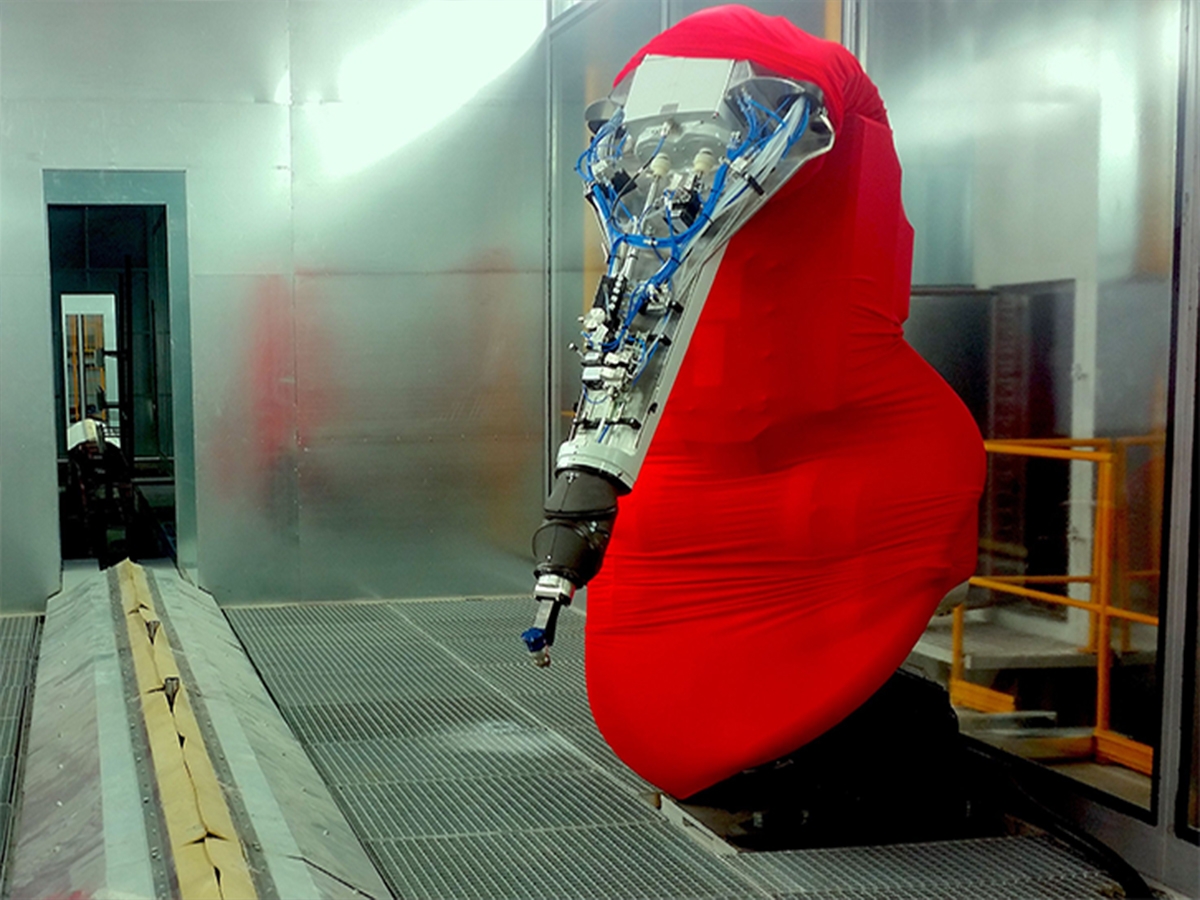

Wet Paint and Powder coating application by Robot

Today, robotic systems are preferred for high capacity, sensitive paint applications, consistent quality production and cost-consciousness. Depending on the dimensions of the part, 6-axis, 7-axis or gantry systems are preferred.

Advantages of Boysis robotic application over manual application

- The amount of paint sprayed is reduced.

Manually applied paint also depends on the performance of the operator. Using different types of guns and bells that can be used by robots, the paint saving is close to 50% compared to manual systems. Solvent and hardener, the components that make up the paint, are also saved at these rates.

- Cleaning and filtration costs are reduced

In parallel with the reduction in paint waste, the consumables used for filtration and the amount of waste sent for treatment are also reduced.

- Energy costs are reduced

In manual applications, 100% fresh air is used for the health of the operator. 90% of the conditioned air in robotic lines can be reused. This reduces the energy used for seasonal heating and cooling of cabin air circulation.

- Retouching costs are reduced

In robotic applications, the paint thickness and quality approved after testing is always repeated. Apart from parts and hanging problems, there are no issues that require retouching. In manual applications, the retouching rate increases mainly due to paint bleed and thickness.

- Colour change costs are reduced

With robotic application, the ability to mix the paint and hardener in the robotic arm minimises paint and hardener waste during colour changes or at the end of the application.

On the other hand, the fact that robotic application is less flexible, requires more skilled personnel and requires more precise air conditioning can be considered as disadvantages.

See Also

- Air Supply Units

- Paint Preparation, Circulation systems, Automatic mixing units, Pig for colour changing system.

- Wet Paint Application Lines