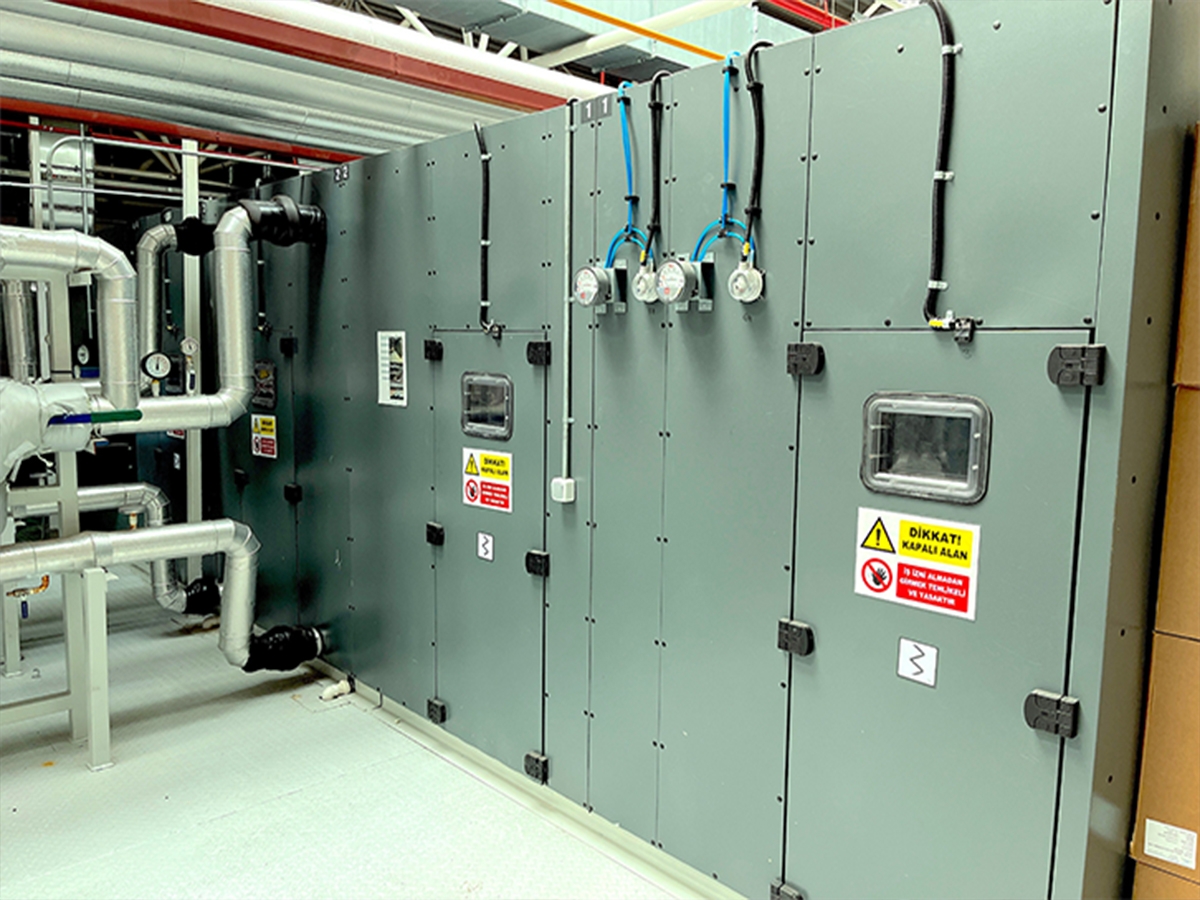

Air Supply Units

Proper ventilation of paint booths is absolutely crucial for ensuring high-quality paint, protecting personnel and robots working in the cabin, and maintaining safety.

The supply air must be filtered and then heated, cooled, or humidified based on the type of paint and the sensitivity of the painting process.

The heating method used must be carefully selected based on the energy resources available in the facility where the paint application will be installed, such as hot water, direct or indirect natural gas burners, or electric heating.

The chiller unit supplies cold water for cooling or dehumidification. In extremely sensitive operations, such as painting aircraft engines, supercooled chillers are utilized for dehumidification.

Humidification is accomplished through a high-pressure atomizer operating at 70 bars. The system introduces dry steam from the steam generator to achieve accurate humidity ratios and changes, as required.

The cabins are supplied with recycled air that has passed through extra filters, while the chiller units incorporate a heat recovery system to maximise energy savings. Boysis's sister company, Luftsis, designs and produces all the necessary systems for robotic applications, including the air supply unit, which features an additional heating coil system.

Rest assured that all of these systems are expertly crafted and produced by Luftsis's professional team.

See Also

- Paint Preparation, Circulation systems, Automatic mixing units, Pig for colour changing system.

- Wet Paint and Powder coating application by Robot

- Wet Paint Application Lines

- Luftsis