Surface Treatment Systems

The surface preparation process used to prepare finished materials for painting is one of the most important factors affecting the paint quality of the product.

Solvent, acid and alkaline cleaning chemicals are applied to the material surface to remove oil, weld contaminants and similar contaminants formed on the material surface during the manufacturing phase prior to painting.

The surface preparation process, which has no protective function of its own, is used to remove contamination from the material surface and to make the surface suitable for adhesion of the organic paint to be applied later.

The surface preparation process, which is carried out by sequentially applying a series of chemicals to the material under appropriate conditions, removes surface contaminants, increases corrosion resistance by changing the chemical structure of the surface and facilitates paint adhesion.

Basically, two types of surface preparation methods are used: "dip type surface preparation" and "spray type surface preparation"

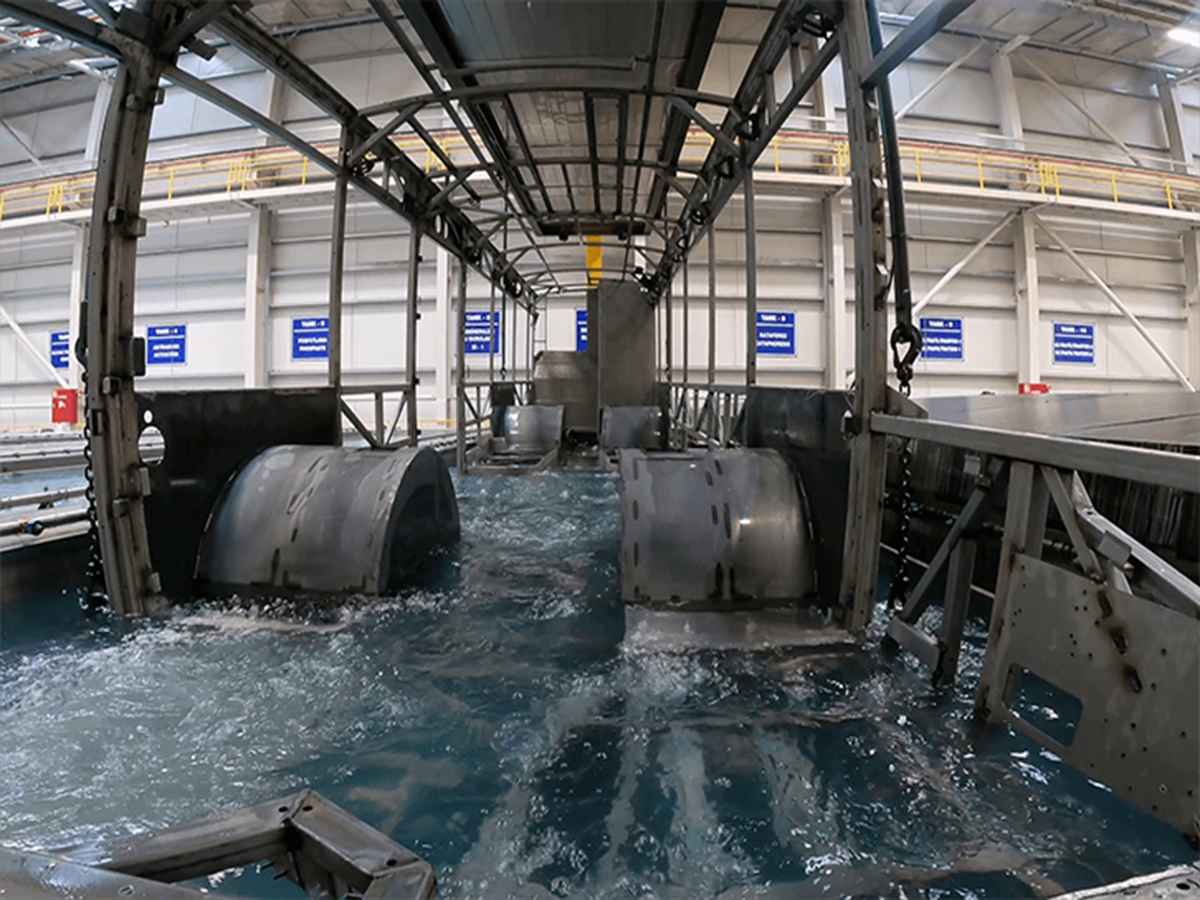

In immersion surface preparation systems, the material is completely immersed in the chemical tank. It is particularly advantageous for penetrating chemicals into every part of complex materials.

In spray type surface preparation systems, chemicals are sprayed onto the material using special nozzles. As it also uses the physical effect of cleaning, a more effective surface cleaning is achieved.

Combined spray and immersion systems can also be installed to take advantage of both methods.